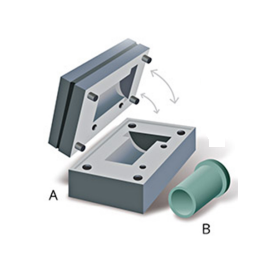

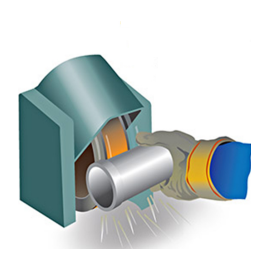

1. Tooling and Pattern Making

A tool is built to customer-provided specifications(A). Cold wax is then injected into the tool to create a wax pattern/prototype (B) that will hold precise dimensional requirements in the final casting.

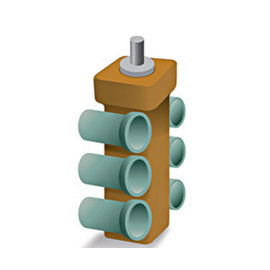

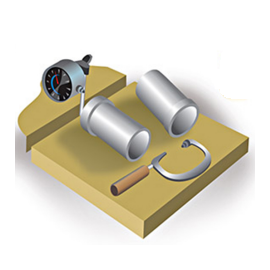

2. Pattern Assembly

The wax patterns are assembled onto the sprue.

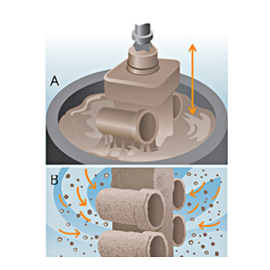

3. Dipping and Coating

Successive layers of ceramic(A) and stucco(B) are applied to the sprue assembly to form a hard shell.

4. De-Waxing and Firing

The molds are flash-fired to remive the wax and sprue materials and then heated to 1,800 and placed on a sand bed,ready for pouring.

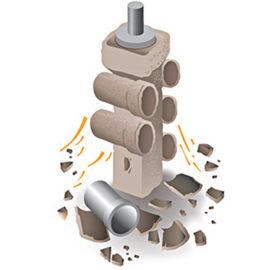

5. Casting

Molten metal up to 3,000, is poured into the hollow mold and then cooled..

6. Knockout

The ceramic shell is briken off, and the individual castings are cut away.

7. Finishing

Excess metal is removed, surfaces are finished, and castings are heat treated.

8. Testing and Inspection

Castings undergo thorough testing and inspection to ensure that they meet dimensional tolerances and specifications.

9. Packing and Shipping

Casting are securely packaged for shipping to the customer.